Tips for Warehouse Fire Safety

With the rising number of fire incidents, ensuring warehouse fire safety has become more important than ever. Fires in warehouses can be caused by a variety of factors, such as electrical malfunctions, faulty equipment, and human error. As a result, it’s essential for warehouse owners and managers to take proactive steps to prevent these dangerous situations. By implementing strong fire prevention strategies, conducting regular inspections, and providing employee training, businesses can significantly reduce the risk of fires occurring.Four Essential Tips for Fire Prevention

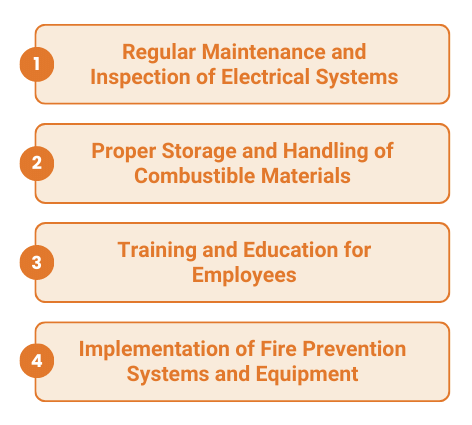

Fire prevention is not just about reacting to danger—it's about anticipating it. A comprehensive approach that includes routine maintenance, staff education, and advanced fire detection systems is key to keeping your warehouse safe. Here are four practical tips to help you prevent fires:

1. Regular Maintenance of Electrical Systems

Electrical issues are one of the leading causes of warehouse fires. To avoid this, schedule regular inspections and maintenance of all electrical components, including wiring, panels, and equipment. This helps identify potential hazards before they lead to a fire.2. Safe Storage of Flammable Materials

Many items stored in warehouses, like cardboard, wood, and paper, are highly flammable. Store these materials away from heat sources and ensure they’re stacked properly to prevent tipping or collapse. Keeping combustible items organized and separated can greatly reduce fire risks.3. Employee Training on Fire Safety

Employees are often the first line of defense against fires. Make sure everyone receives proper training on how to handle flammable materials, use fire extinguishers, and respond in an emergency. Regular drills and refresher courses can help reinforce these important skills.4. Installing Fire Detection and Suppression Systems

Modern fire prevention systems, such as smoke detectors, alarms, sprinklers, and suppression equipment, can detect and control fires quickly. These systems provide early warning and can make a critical difference in preventing major damage.

Preparing for Emergencies: The Importance of an Emergency Plan

No matter how well-prepared you are, emergencies can still happen. That’s why having a clear and effective emergency response plan is crucial. A good plan ensures that employees know what to do, where to go, and how to stay safe during a fire or other disaster. Your emergency plan should include: - Clear roles and responsibilities for each team member. - Designated escape routes and assembly points. - A communication strategy to keep everyone informed. - Regular testing and updates to ensure the plan stays current. By preparing in advance, you can protect your people and minimize property damage.Protect Your Warehouse with MoviTHERM’s Advanced Fire Detection Solutions

Preventing warehouse fires is essential for safeguarding your workers, assets, and business continuity. MoviTHERM offers cutting-edge solutions designed to detect early signs of fire and monitor equipment conditions in real time. Their thermal imaging cameras can identify temperature changes that traditional smoke detectors might miss, giving you valuable time to act before a fire spreads. Additionally, their condition monitoring systems help detect overheating or abnormal behavior in equipment, allowing for timely maintenance and reducing the risk of fire. With MoviTHERM, you gain a proactive approach to fire safety—ensuring that potential threats are identified and addressed before they escalate. Learn more about how MoviTHERM can enhance your fire prevention strategy today.New Products Of Glass Installation Robot

The Smart Glass Installation Robot is a state-of-the-art machine that combines movement, lifting, rotation, tilting, and vacuum grabbing capabilities for automatic installation. It is the perfect solution for installing glass windows, glass curtain walls, and other glass components on buildings such as airports, exhibition halls, hotels, museums, shopping malls, and more. With just one operator, it can complete all installation tasks, and all functions can be controlled remotely. The robotic arm can adjust the installation angle accurately, making it highly precise and efficient.

We offer several models of this robotic system with load capacities ranging from 300kg to a maximum of 1200kg. It can work both on the ground outside and inside elevators, reaching any floor. The vacuum lifter is powered by two high-capacity batteries, ensuring uninterrupted operation for up to 6-8 hours.

The Smart Glass Installation Robot can handle glass panels of various sizes, even curved glass, with different suction heads. It is designed for easy maneuvering and control, making it suitable for a wide range of installation tasks. Whether it's a small or large glass panel, the Smart Glass Installation Robot can handle it with ease, ensuring a professional installation every time.

Glass Setting Robot,smart glass installation,Easily Glass Installation

Guangdong Cowest Machinery Equipment Co.,ltd. , https://www.cowestmac.com