Saving Over $1 Million: Wind Turbine Inspections With The Elios 3

Key Benefits At A Glance

|

Safety The Elios 3 allows for safe access to the interior of wind turbine blades without requiring personnel to enter dangerous or confined spaces. This significantly reduces the risk of accidents and injuries during inspections. |

Speed With the Elios 3, inspection efficiency is doubled. It can inspect up to 4 turbines in a single day, while traditional methods typically manage only 1 to 2 per day. This results in faster turnaround times and more frequent checks. |

|

Costs Identifying faults early with the Elios 3 can save over $1 million per wind turbine blade by preventing costly replacements and reducing maintenance expenses. |

Access Wind turbines can be over 170 feet tall (52 meters), making access difficult and dangerous. The Elios 3 provides straightforward access to these heights, minimizing human exposure and fall risks. |

Wind energy has been a part of human history since ancient times, starting with windmills used for grinding grain and pumping water. Today, it plays a vital role in generating clean electricity. In 2022, wind power accounted for 7.33% of global energy production.

However, wind turbines are highly complex structures that require careful construction, transportation, and regular inspection. A single blade for a land-based turbine can be over 170 feet long (52 meters). The largest turbine in the world, the Goldwind GWH252-16MW, has a rotor diameter of 827 feet (252 meters), making inspections even more challenging.

Inspecting wind turbines is essential to ensure their safety and performance. It helps identify issues such as cracks, grease buildup, or missing bolts—problems that could lead to serious failures or even fires. Traditional methods often involve working at great heights or in tight, hazardous spaces, which can be both time-consuming and risky.

The Elios 3 is changing the game. Used by companies like Pathfinder Optics, this drone enables safer, faster, and more cost-effective inspections of some of the largest wind turbines in the U.S.

Developing Drone Inspections For The Renewable Energy Industry

Joseph Valenzuela, Operations Manager at Pathfinder Optics, is a seasoned drone pilot who started his career as a non-destructive testing technician. He quickly realized that many inspections required working at height or in confined areas, so he turned to robotics as a safer alternative. That passion led to the founding of Pathfinder Optics, a company specializing in robotic and drone inspections across multiple industries.

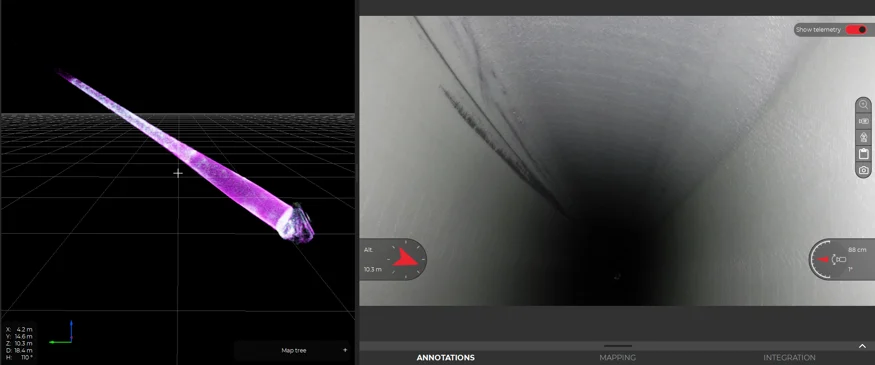

Pathfinder Optics now uses a fleet of advanced drones and robotics to conduct inspections. One of their key areas of expertise is wind turbine inspections, where Joseph relies on the Elios 3. He highlights the LiDAR capabilities of the drone, which provide detailed data that enhances the quality of his inspections and gives him a competitive edge.

How Drones Can Be Used For Wind Turbine Inspections

Initially, Joseph used a standard rotary drone for turbine inspections, but found it lacked the protection needed for tight spaces. The Elios 3, with its protective cage, allows him to move confidently inside the narrow interiors of turbine blades, collecting critical visual and LiDAR data.

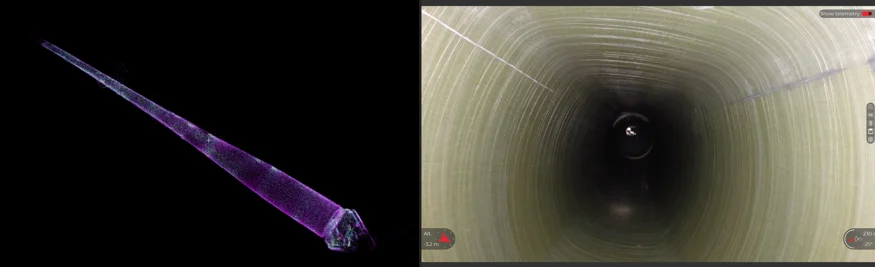

During a recent project, Joseph inspected four turbines in one day. Each turbine had to be turned off, and the blades were stationary before the inspection began. He climbed to the hub, where he accessed each blade using the Elios 3. The compact design of the drone made it easy to maneuver through tight spaces, and the LiDAR provided accurate measurements and visual feedback.

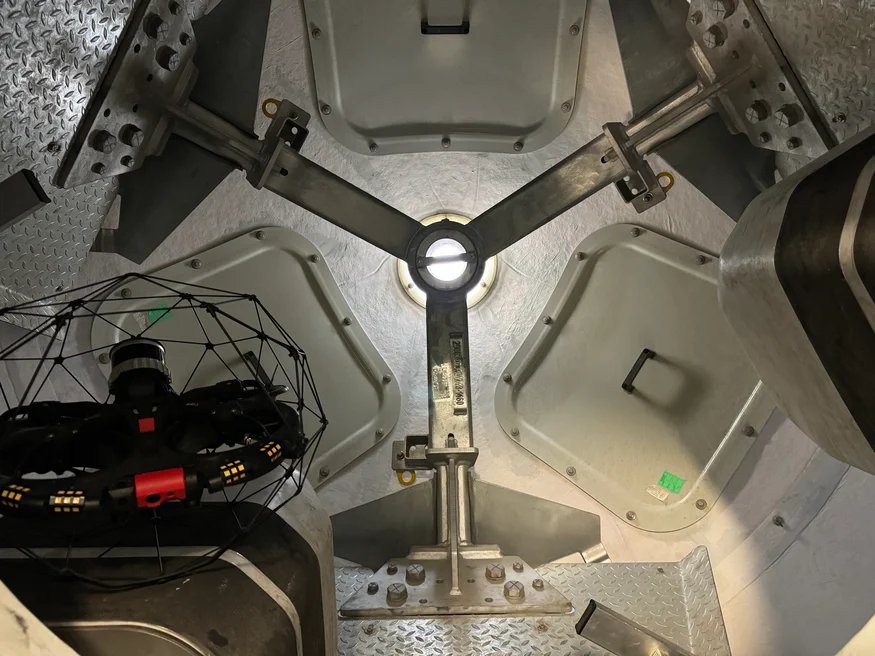

The small area from where Joseph can access the separate wind turbine blades

The small area from where Joseph can access the separate wind turbine blades

One of the biggest challenges was access. Joseph had to climb a ladder to reach the hub while carrying the drone. At some sites, the drone could also be winched up as he climbed. Once inside, he used the Elios 3 to navigate down the length of each blade, collecting data before returning to the hub.

This method allowed Joseph to complete four inspections in a single day—an achievement that would have been nearly impossible with traditional methods, which often limit inspectors to one turbine per day.

With the Elios 3, Joseph not only improves safety but also increases productivity. His workflow is efficient, allowing him to inspect a turbine and return to the ground within three hours—a significant improvement over previous methods that could take half a day or longer.

Benefits Of Using A Drone For Wind Turbine Inspections

The visual and LiDAR data collected by Joseph are crucial for monitoring the condition of wind turbines. While the control system (CMS) manages how the blades pitch and rotate, it cannot detect damage to the fiberglass blades themselves. That’s where inspections come in—identifying issues early can prevent expensive repairs or replacements.

A damaged blade can cost over $1 million to replace. By using the Elios 3, Joseph can spot problems before they escalate, helping turbine owners avoid major financial losses. Lightning strikes, for example, can cause catastrophic damage if the lightning protection system isn’t properly configured. The Elios 3 helps identify potential hazards before they become disasters.

The interior of the wind turbine is clearly visualized with the Elios 3's LiDAR scan

The interior of the wind turbine is clearly visualized with the Elios 3's LiDAR scan

Joseph uses the Elios 3 to identify manufacturing defects or hidden dangers inside the blades. He then reports these findings to the turbine owner or manager, who can act quickly to schedule maintenance or plan a replacement. This proactive approach saves money and prevents unplanned downtime.

Annual or biannual inspections are required by law in many regions, and traditionally involved workers entering the blades—posing a serious fall risk. Now, with the Elios 3, those risks are minimized, and inspections are completed faster and more safely.

In emergency situations, such as a turbine fire caused by lightning or a grease leak, the Elios 3 allows for rapid response. Instead of sending personnel into danger, Joseph can fly the drone to assess the situation and provide real-time information, helping decision-makers respond more effectively.

Bringing Modern Drone Technology To Renewable Energy

Joseph has found that the Elios 3 has transformed his work. “I’m not a fan of heights,†he says. “This drone lets me work quickly and safely without having to spend too much time in dangerous areas.†He emphasizes that inspecting turbine blades is inherently risky, both physically and psychologically. The Elios 3 keeps him safe in the hub, where he can be harnessed and monitored without needing to crawl into the blades.

Jospeh is conducting safer turbine inspections with the drone and working faster than ever

Jospeh is conducting safer turbine inspections with the drone and working faster than ever

Since Pathfinder Optics began offering wind turbine inspections, Joseph has worked on projects along the West Coast of the U.S. He knows that using the Elios 3 not only makes inspections safer but also helps turbine owners save money and avoid costly damage. All of this is possible thanks to the Elios 3’s ability to operate safely in tight, high places.

Discover more about the Elios 3 and its specialized LiDAR payload.

All images in this article are credited to CLP Power.

Coffee Grinder,Best Coffee Grinder,Bean Grinder,Burr Coffee Grinder

Heshan Zilong Home Appliance Technology CO.Ltd , https://www.techonele.com