Saving Over $1 Million: Wind Turbine Inspections With The Elios 3

Key Benefits At A Glance

|

Safety The Elios 3 allows for safe access to the interior of wind turbine blades without requiring personnel to enter dangerous or confined spaces. This significantly reduces risk and ensures a safer working environment. |

Speed With the Elios 3, inspections are twice as fast. It can inspect up to four turbines in a single day, whereas traditional methods usually only manage one or two per day. |

|

Costs Identifying faults early with the Elios 3 can save over $1 million per wind turbine blade by reducing replacement costs and minimizing downtime. |

Access Wind turbines can be over 170 feet tall, making access difficult. The Elios 3 provides straightforward access to these towering structures, reducing human exposure and fall risks. |

Wind energy has been around for centuries, starting with windmills used for agriculture and power generation. Today, wind turbines play a crucial role in powering the world. In 2022, wind energy accounted for 7.33% of global electricity production.

Despite their importance, wind turbines are complex to build, transport, and maintain. A single blade can be over 170 feet long, and the largest turbines have rotors that span over 800 feet. These massive structures require careful inspection to ensure they operate safely and efficiently.

Inspecting wind turbines is not just about checking for damage — it's also about ensuring lightning protection systems are properly installed and identifying potential hazards like grease buildup or missing bolts. These issues can become dangerous if left unchecked, especially during a lightning strike.

The Elios 3 is being used by Pathfinder Optics to conduct safer and more efficient inspections on some of the largest wind turbines in America.

Developing Drone Inspections For The Renewable Energy Sector

Joseph Valenzuela, Operations Manager at Pathfinder Optics, started his career as a non-destructive testing technician before transitioning into drone operations. He recognized the need for safer and more efficient inspection methods, which led him to develop a specialized robotics and drone inspection company.

Pathfinder Optics now uses a fleet of advanced drones, including the Elios 3, to inspect wind turbines across multiple industries. Joseph credits the LiDAR capabilities of the Elios 3 as a game-changer, allowing for more accurate and detailed inspections that outpace competitors.

How Drones Are Revolutionizing Wind Turbine Inspections

Joseph initially used a standard rotary drone but found that the Elios 3 was the ideal tool for the job. Its protective cage allows safe navigation inside the tight spaces of turbine blades, while its LiDAR and visual data provide critical insights needed for thorough inspections.

During a recent project, Joseph inspected four turbines in a single day. Each turbine required climbing to the hub and navigating inside the blades. The Elios 3’s portability made this process much more efficient, and in some cases, the drone could even be winched up while he climbed.

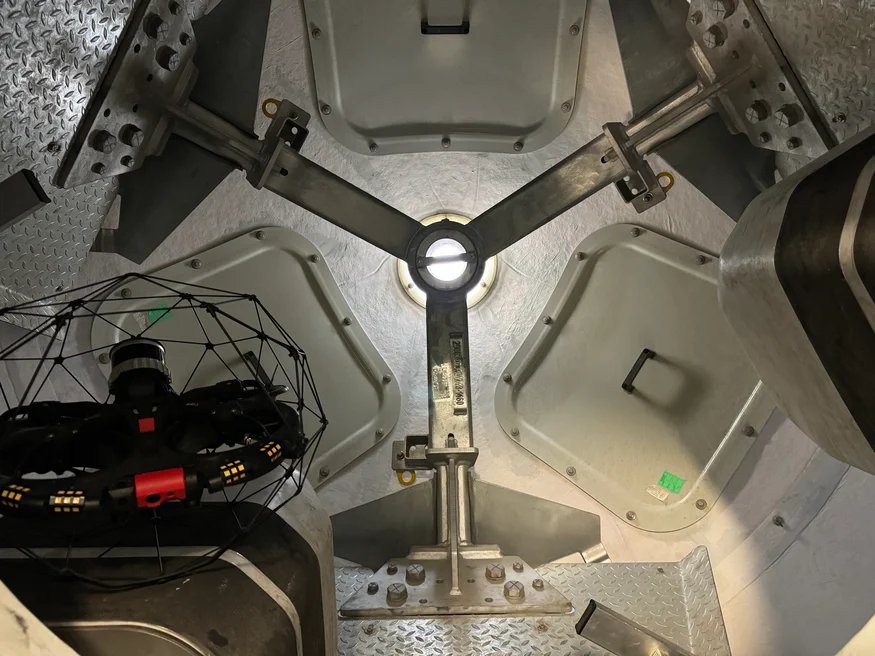

The small area from where Joseph accesses the turbine blades

The small area from where Joseph accesses the turbine blades

Inside the hub, Joseph had limited space to work, but the Elios 3 allowed him to move confidently through the narrow passages. Each blade could be inspected within one battery life, and after completing all four, he safely descended back down.

This method would be nearly impossible with traditional inspection techniques, which often limit operators to one turbine per day.

Image right: The Elios 3 makes it easy to inspect the cramped interior of turbine blades, saving time and effort for inspectors.

Why Drones Are Essential For Wind Turbine Maintenance

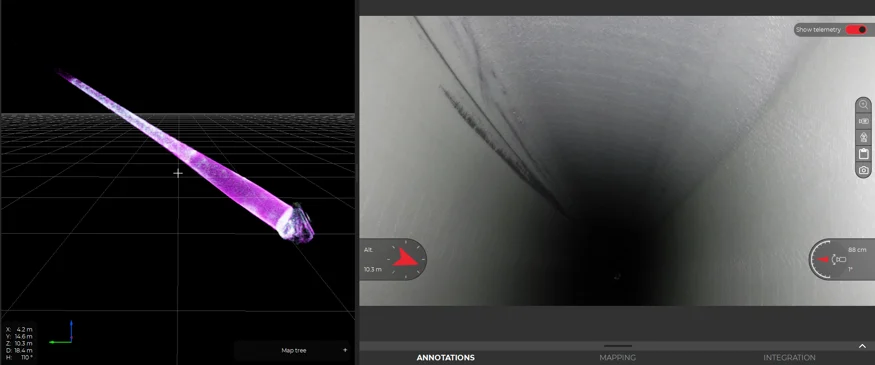

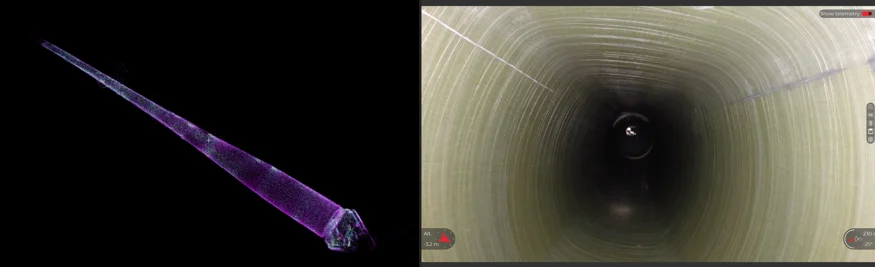

Using the Elios 3, Joseph conducts both visual and LiDAR scans, which are essential for monitoring the condition of wind turbines. While the CMS (Condition Monitoring System) tracks how the blades pitch and rotate, it cannot detect internal damage caused by cracks, moisture, or manufacturing defects.

A damaged blade can cost over $1 million to replace, and early detection is key to avoiding such expenses. Lightning strikes, for example, can cause catastrophic failures if the protection system is not properly configured. Grease buildup can also increase the risk of fire or explosion during a lightning strike.

The Elios 3 provides clear visualization of the turbine’s interior with LiDAR scanning

The Elios 3 provides clear visualization of the turbine’s interior with LiDAR scanning

By using the Elios 3, Joseph can identify potential issues early and report them to turbine owners, who can then take swift action. This proactive approach saves money and prevents costly repairs or replacements.

Annual or biannual inspections were once a risky task for workers, who had to crawl inside the blades or walk along the structure. Now, with the Elios 3, safety is prioritized, and the process is faster and more efficient.

In emergencies, such as a turbine fire or grease leak, the Elios 3 allows for rapid response without putting personnel at risk. Joseph can quickly assess the situation and provide real-time data, enabling quick decision-making without exposing anyone to danger.

Modern Drone Technology Is Transforming Wind Energy

Joseph says that the Elios 3 has revolutionized his work. “I’m not a fan of heights, and this drone helps me work quickly and safely,†he explains. “It minimizes the time I spend in high-risk areas and keeps me protected inside the hub.â€

Joseph inspects turbines faster and safer with the Elios 3

Joseph inspects turbines faster and safer with the Elios 3

Since implementing the Elios 3, Joseph has completed projects along the West Coast of the U.S. He knows that using the drone not only improves safety but also helps wind farm owners save money and avoid costly damage from lightning or other issues.

By relying on the Elios 3, Pathfinder Optics continues to lead the way in modernizing wind turbine inspections, making the renewable energy sector safer and more efficient.

Discover more about the Elios 3 and its advanced LiDAR technology.

All images in this article are credited to CLP Power.

Smeg Bean To Cup Coffee Machine,Pump-Driven Espresso Machine,,Best Automatic Espresso Machine

Heshan Zilong Home Appliance Technology CO.Ltd , https://www.techonele.com